Technology and Innovation in E-Waste Recycling

Technology and innovation are redefining how India manages its growing electronic waste crisis. As one of the world’s top producers of e-waste, India generates over 1.6 million tonnes annually, according to CPCB data. But within this challenge lies an immense opportunity. Through the power of emerging technologies and innovative recycling models, e-waste is being transformed from an environmental hazard into a sustainable economic resource.

The future of e-waste management depends not just on regulations but on how efficiently technological advancements and creative innovations come together to create scalable, green solutions.

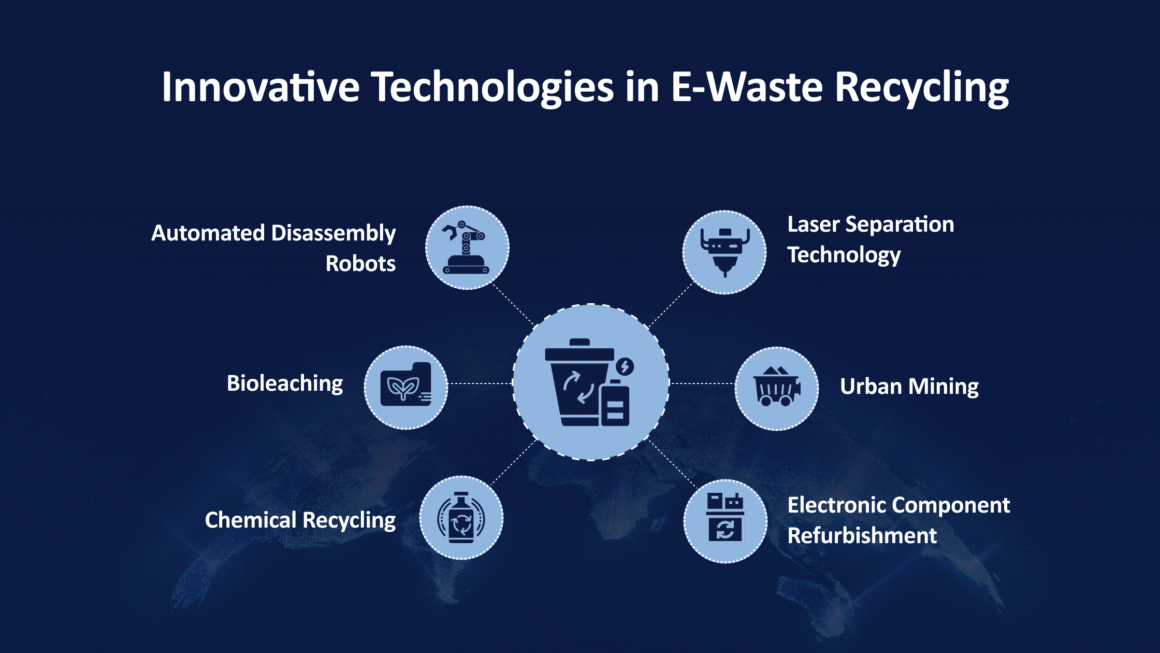

From robotics to blockchain, India’s e-waste sector is undergoing a digital and industrial transformation. These technologies are not just improving recycling efficiency; they are rewriting the future of sustainability, circular economy, and green jobs.

The Evolution of E-Waste Recycling in India

For decades, e-waste management relied on informal, unregulated practices — manual dismantling, acid leaching, and open burning. This system created jobs but caused widespread pollution. Now, India’s E-Waste Management Rules 2022 and the rise of smart technologies are formalizing the sector.

Government initiatives like Digital EPR Portal and Swachh Bharat Mission 2.0 have enabled better tracking, transparency, and awareness. At the same time, tech startups are introducing innovative solutions that make recycling cleaner, more profitable, and data-driven.

Artificial Intelligence (AI) and Robotics in E-Waste Recycling

a) Robotic Disassembly

AI-powered robots can now identify, sort, and dismantle electronics at lightning speed. Using machine vision and deep learning, these robots detect valuable components like motherboards and batteries for targeted recovery.

- Apple’s “Daisy Robot” can disassemble 200 iPhones per hour, recovering lithium, gold, and cobalt efficiently.

- Indian startups are piloting robotic dismantling lines in Bengaluru and Pune, reducing toxic human exposure.

b) Automated Sorting Systems

Advanced optical and magnetic sensors use AI algorithms to classify plastics, metals, and glass, boosting recycling accuracy by over 95%. This automation drastically cuts labor dependency while enhancing throughput.

IoT and Data Analytics for Smart Recycling

The Internet of Things (IoT) has brought intelligence to waste collection and tracking.

- IoT-enabled bins and collection devices transmit data on fill levels, ensuring optimized collection routes and energy-efficient logistics.

- Real-time monitoring allows CPCB and recyclers to track the life cycle of e-waste, from consumer disposal to final recovery.

- Predictive analytics can forecast waste generation patterns across cities, helping policymakers design smarter recycling networks.

Blockchain for Transparency and Trust

Blockchain technology is transforming e-waste management into a transparent and traceable system.

- Each stage of the recycling chain — collection, transport, dismantling, smelting — is recorded in an immutable ledger.

- Smart contracts automatically verify compliance, ensuring producers meet Extended Producer Responsibility (EPR) targets.

- Fraudulent recycling certificates and “ghost recovery” claims can be eliminated.

Startups like Recykal have already implemented blockchain-powered traceability solutions that link recyclers, producers, and waste collectors under one digital umbrella.

Advanced Material Recovery Innovations

a) Hydrometallurgy and Pyrometallurgy

New extraction methods using chemical leaching, ionic liquids, and high-temperature smelting allow recovery of precious and rare-earth metals with up to 99% purity. These metals — gold, palladium, lithium, cobalt — are critical for the renewable energy and EV industries.

b) Bioleaching: Nature’s Green Chemistry

In this eco-friendly method, microbes like Acidithiobacillus ferrooxidans extract metals naturally. Bioleaching reduces chemical use and CO₂ emissions, making it ideal for green recycling.

c) Micro-Recycling and Modular Units

Compact recycling units that process small batches of e-waste are emerging across India. They are energy-efficient, scalable, and suitable for decentralized recycling near urban centers.

Clean Recycling and Net-Zero Integration

Recycling itself must be sustainable. India’s new Net-Zero E-Waste Eco Park in Delhi is a pioneering model:

- Built on a ₹150 crore investment, it will process 50,000+ tonnes of e-waste annually.

- Operates on 100% renewable power and smart emission management.

- Incorporates AI-based sorting, IoT logistics, and carbon-tracking systems.

This facility is a blueprint for net-zero waste management, aligning with India’s 2070 climate neutrality goals.

The Role of Digital Platforms and Circular Startups

Platforms like Karo Sambhav, Recykal, and Cerebra Green are integrating digital tools, logistics, and recycling certifications. They connect consumers, producers, and recyclers, creating transparency and efficiency.

These startups are key to building a circular economy, where products, components, and materials retain value over multiple lifecycles.

Challenges Hindering Technology Adoption

Despite remarkable progress, the path to fully automated recycling faces hurdles:

- Cost: High upfront investment in robotics and hydrometallurgy deters small recyclers.

- Informal Sector Dominance: Over 80% of India’s e-waste still moves through informal networks.

- Lack of Skilled Labor: Advanced technology needs trained technicians and engineers.

- Limited Awareness: Many consumers remain unaware of e-waste collection systems.

To overcome these, India needs policy support, subsidies, R&D incentives, and training programs for recyclers and workers.

The Economic and Climate Benefits

- Metal Recovery: Recycling 1 tonne of e-waste can yield up to 300 grams of gold, 100 kg of copper, and 50 kg of aluminum.

- Emission Reduction: Formal recycling could cut 4–5% of India’s industrial emissions by 2035.

- Job Creation: The industry could generate 500,000 green jobs over the next decade.

- Circular Value: The recovered metals could supply India’s EV, battery, and renewable sectors.

Future of E-Waste Recycling: India’s Innovation Roadmap

To make technology-driven recycling mainstream, India must:

- Link carbon credits to verified recycling output.

- Expand R&D collaboration between IITs, BARC, and private recyclers.

- Adopt global best practices — such as Japan’s appliance recycling model and Germany’s carbon-linked circular policy.

- Develop green financing tools to support e-waste tech startups.

- Integrate informal recyclers into the formal chain via training and certification.

Conclusion: Technology and Innovation in E-Waste Recycling

The convergence of technology, policy, and innovation has turned e-waste recycling from a pollution problem into a profit-driven sustainability opportunity. With robotics dismantling devices, AI predicting material flows, and blockchain ensuring transparency, the recycling industry is entering its smartest phase yet.

If scaled efficiently, India’s innovation-led recycling sector could not only make the country a leader in circular economy but also a cornerstone of the world’s green tech transition.

FOR MORE BLOGS – beyondthepunchlines.com

Add to favorites

Add to favorites